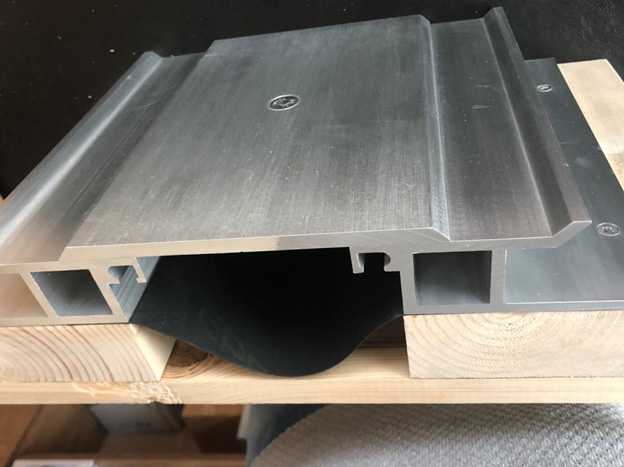

Execution of profiles in discontinuity and expansion is done in two ways: built-in and surface.

Depending on the type of project and the stage in which the project is located, how to install the profiles for discontinuity and expansion joints is determined. If the work is in the early stages and the joints of the discontinuous joints have not been finished, the desired substructure can be done and the desired built-in profile can be installed.

Depending on the type of application and the type of project and the steps of the work, the profiles of discontinuity and expansion joints are designed. According to the type of project and the type of structure and the material of the structure and its height, the size of discontinuity joints varies. (June seam profiles) are produced in different sizes and the most used sizes are from 2 cm to 20 cm.

In traffic parts, due to the load applied to the discontinuous seam coverings, the size of the gaps is usually less than 20 cm. Background (expansion and discontinuity joint profiles) has many capabilities in the field of design and production of this material.

In many projects, these sizes are reduced, but in many projects, they proceed with their standards, considering that the size of the discontinuous joints should not be reduced structurally.

Of course, in terms of costs, the smaller the seam allowance (June seam), the smaller it is.

Technically, it is better not to change the size of the discontinuous joints.

Applications of discontinuous seams

- In the parts where there are parking lots, traffic and car profiles are used that can withstand traffic loads.

- In the parts that are internal, person profiles and light traffic are used.

- In the June seam, the roof and wall facade parts are also used for its special types.